Induction Furnace Manufacturer

Melting Solutions for Metal Processing

Induction furnaces manufacturer in India, ensuring durability, high productivity, and energy efficiency for industrial metal melting. We specialise in induction melting furnaces and metal processing solutions for foundries and steel plants worldwide.

We Are manufacturing

Induction melting furnace

Efficient and reliable melting solution tailored for aluminium foundries and casting operations.

Precision-engineered furnaces for fast and clean melting of brass and bronze alloys.

High-efficiency induction system designed for consistent and oxidation-free copper melting.

Heavy-duty furnace engineered for high-temperature steel melting in industrial environments.

Compact, high-precision furnace ideal for gold, silver, and other precious metal applications.

Specialized furnace for investment casting processes with rollover mechanism for safe pouring.

Designed for fast batch processing with an easy push-out mechanism for molten metal discharge.

Robust steel shell furnace built for durability under continuous, high-capacity melting operations.

Compact box-type design optimized for uniform aluminium melting and low energy consumption.

We Are manufacturing

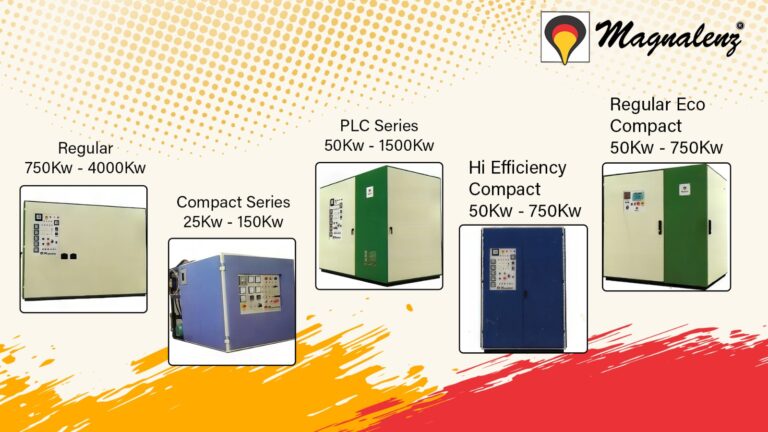

Induction heating machine

High-speed billet heating system for forging, extrusion, and hot forming applications.

Clean and efficient heating solution for precise and repeatable metal brazing processes.

We Are manufacturing

Horizontal continuous caster machine

Advanced HCCM system for uninterrupted and precise casting of aluminium billets or rods.

Engineered for smooth, continuous casting of high-quality cast iron profiles and bars.

Custom HCCM for consistent casting of non-ferrous metals with superior surface finish.

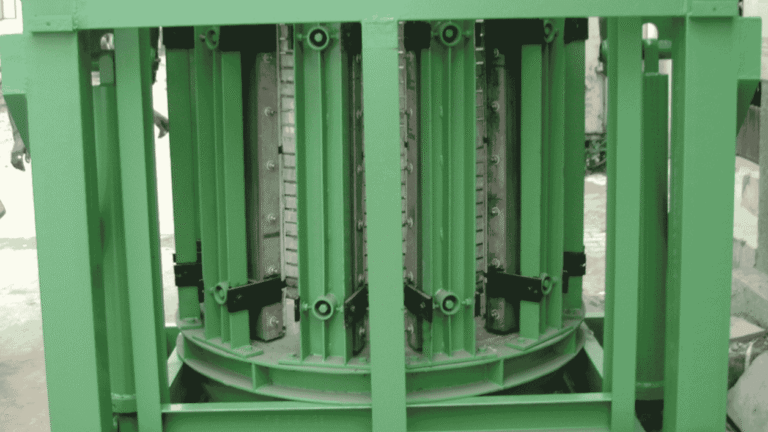

We Are manufacturing

Metal chips briquette machine

Advanced HCCM system for uninterrupted and precise casting of aluminium billets or rods.

Advanced HCCM system for uninterrupted and precise casting of aluminium billets or rods.

We Are manufacturing

Copper Cathode Plant

Copper cathode plant is a facility where copper is refined into high-purity copper cathodes through a process called electrorefining

Induction Melting Solutions

Welcome to Magnalenz

Expertise You Can Rely On

At Magnalenz, we specialise in delivering state-of-the-art induction melting furnaces and metal processing solutions for foundries and steel plants worldwide. Founded by industry veterans with over 25 years of experience, we are driven by a commitment to engineering excellence, custom solutions, and customer satisfaction.

WHY CHOOSE US

What Sets

Magnalenz Apart

Magnalenz is a trusted manufacturer of advanced induction-based melting, heating, casting, and metal recycling systems—delivering high-efficiency, custom-engineered solutions for foundries, steel plants, and metal processing industries worldwide.

Superior Power Control

With Thyristor-Controlled Rectifiers, our furnaces operate efficiently even at low input voltage, offering smooth power regulation from 5% to 100%. The system automatically safeguards itself against short circuits or power failures.

Built-In Safety Margins

Our parallel circuit design ensures thyristors operate at just one-third of their rated current—leading to low thermal stress, extended life, and maximum reliability.

Energy-Efficient Operations

Magnalenz furnaces are optimized for high electrical efficiency (up to 97%), reduced melting time, and consistent power output, which translates to lower melting costs.

High Power Factor

With an average power factor above 0.95, our systems minimize reactive power loss—saving energy and avoiding costly power factor penalties.

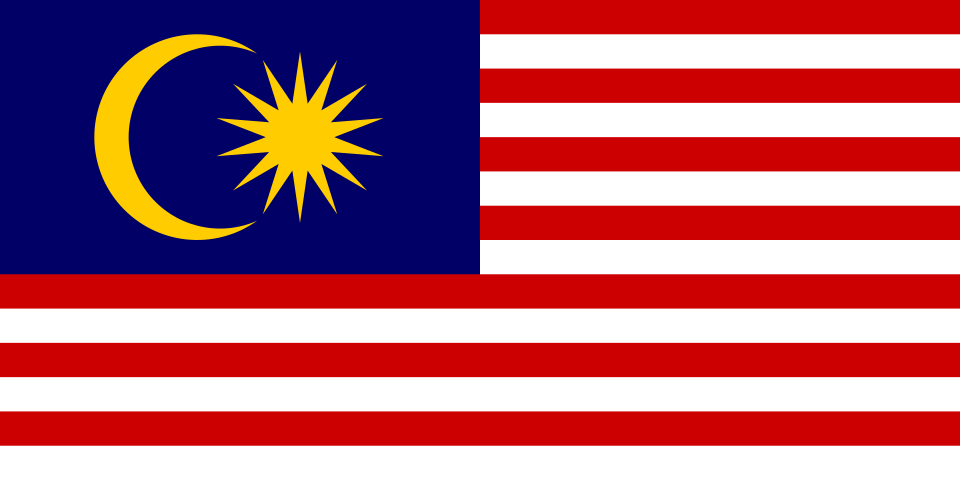

Countries we Export

Global Presence

Sri Lanka

UAE

Iran

Turkey

Kenya

DR of Congo

Sudan

Mali

UK

Poland

Croatia

Indonesia

Malaysia

Philippines

Mexico