Product Description

|

|

|

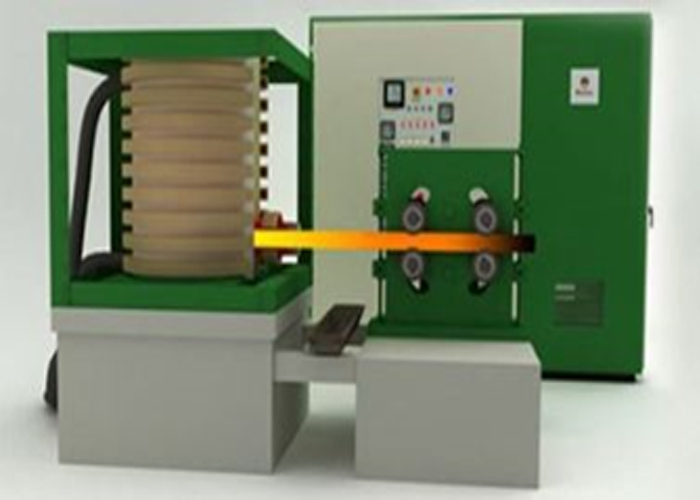

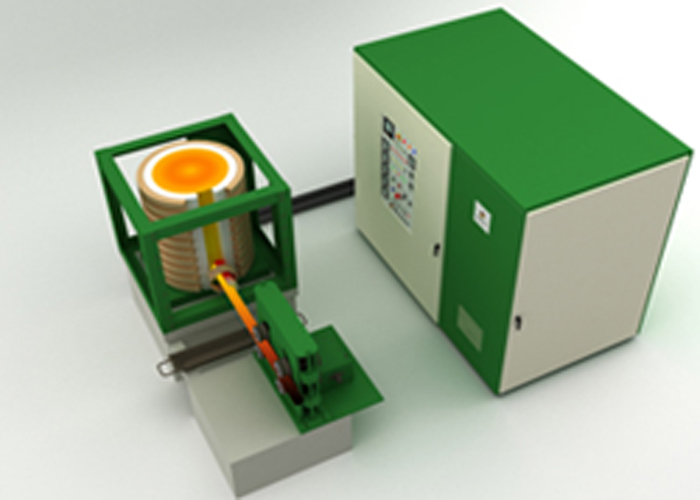

The unique concept of the new generation horizontal continuous casting machine, where controlled flow of molten metal directly from the bottom of the core less medium frequency Induction Melting Furnace, taking shape and solidifies in partly heated and partly water cooled graphite die attached horizontally with the furnace, and pulled by the withdrawal system.

This unique concept of melting and holding in an induction furnace and controlled pulling of molten metal from the bottom part of the furnace is advantageous in many aspects. It is more benefitted over presently available any of horizontal continuous casting machine. At the same time it is safer in operation, easy in product handling and highly productive.

Variety of alloys can be cast in small batches, with faster start-up, uniform metal in composition and in chemistry, fast furnace lining preparation, balanced phasing, high energy efficiency, compact layout, low metal losses are benefits of induction Furnace Based Horizontal Continuous Casting Technology. Multiple die can be used and Die Changing is very easy and fast. Recurring Consumption of graphite crucible, due to oxidation is absent in this system, which reduces the inventory cost and process cost at a large.